PROJECT STATEMENT

To create a 9 volt electric motor allowing the movement of a monorail of 20 x 15 x 15 cm^3, with a minimum mass of 250g. All using only salvaged materials that are not from commercial games, existing equipment, or are electrical. The design may be made of cardboard, wood, metal or plastic. The use of tape and glue is allowed.

Canning wire, magnets and electrical wiring are provided by the school.

Materials: metal canister, deodorant, soldering iron (plus tin to melt), metal pin, drill, hacksaw, plenty of metal tape, strong scissors, very strong glue, copper wire, electric cables, batteries, battery box, two conductive metal tabs.

To create a 9 volt electric motor allowing the movement of a monorail of 20 x 15 x 15 cm^3, with a minimum mass of 250g. All using only salvaged materials that are not from commercial games, existing equipment, or are electrical. The design may be made of cardboard, wood, metal or plastic. The use of tape and glue is allowed.

Canning wire, magnets and electrical wiring are provided by the school.

Materials: metal canister, deodorant, soldering iron (plus tin to melt), metal pin, drill, hacksaw, plenty of metal tape, strong scissors, very strong glue, copper wire, electric cables, batteries, battery box, two conductive metal tabs.

SUMMARY OF THE MAIN POINTS MADE :

MOTOR PLANS

For the realization of our motor we first created the plans of this one starting from a model whose rotor would be made up of resin in paste (Pattex) and of aluminium lamella assembled. We were inspired by models of direct current motors recovered from a company specialising in motors.

MOTOR PLANS

For the realization of our motor we first created the plans of this one starting from a model whose rotor would be made up of resin in paste (Pattex) and of aluminium lamella assembled. We were inspired by models of direct current motors recovered from a company specialising in motors.

CREATION OF THE SECOND ENGINE

It soon became necessary to make a second rotor for our motor. The first one weighed 110g and (as in the video installation) only worked with new batteries.

We cut out two shapes for the rotor from a wooden board

It soon became necessary to make a second rotor for our motor. The first one weighed 110g and (as in the video installation) only worked with new batteries.

We cut out two shapes for the rotor from a wooden board

Fixing these with nuts on a threaded axle and then winding on each of the three branches. We made a commutator with three conductive blades (with conductive tape and a cork) and fixed it with nuts. Contact between the ends of the coils and the commutator blades is then ensured by removing the varnish on the end of the copper wires and placing a piece of tape to clamp the copper wires to the commutator blades.

RESULTS:

We get a motor that runs quite fast and does not consume as much battery as before. It now weighs 56 g, half as much as the previous one. After testing, this motor proved to be too bulky and unstable. So we decided to use the motor provided by the school for the rest of the project.

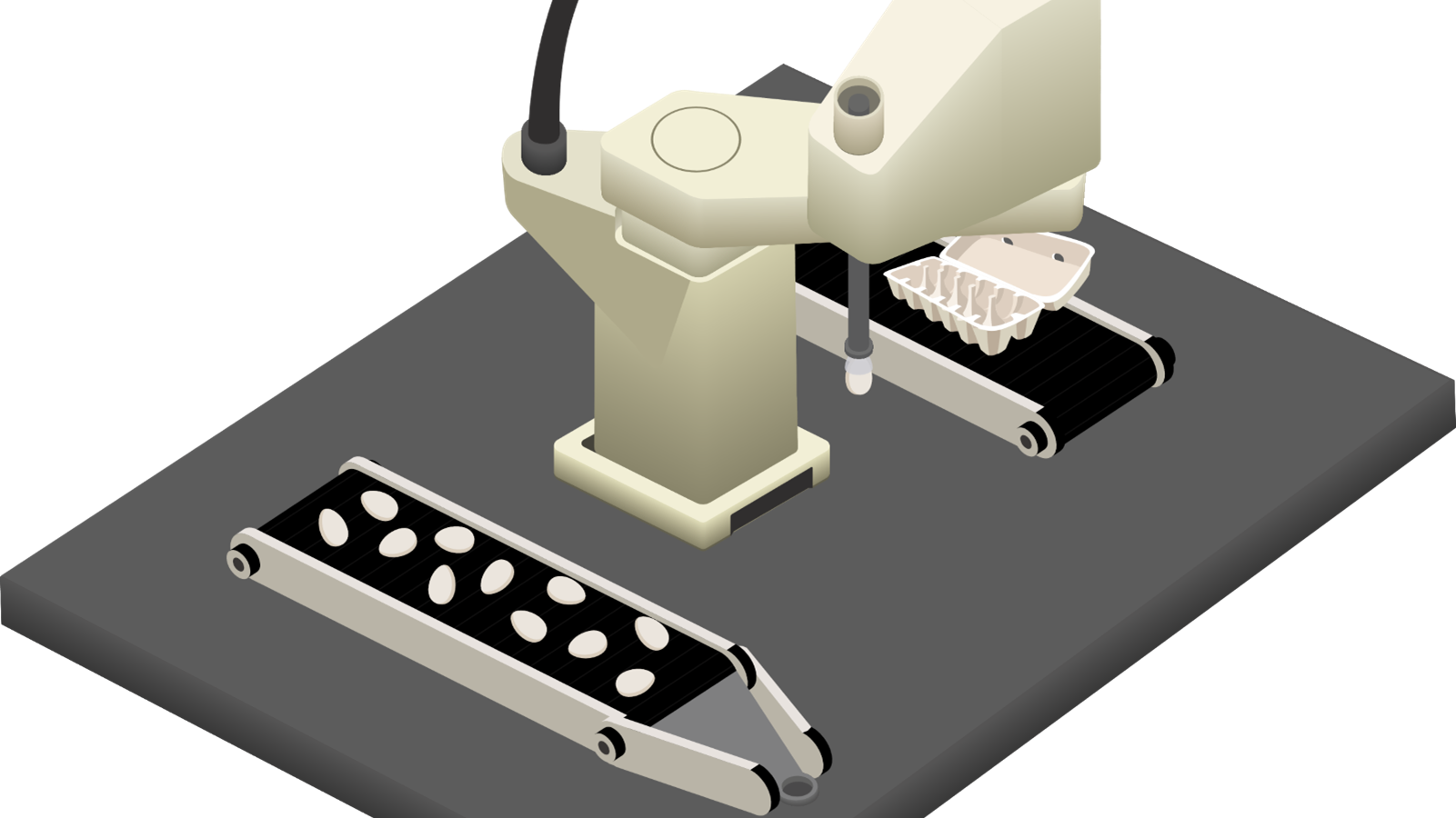

CREATION OF A MINIATURE MOBILE SUSPENDED TRAMWAY:

First of all we studied the train and its transmission system, we decided to take a pulley-belt system with a toothed belt by studying our state of the art.

See the video of the construction of the two trains:

We get a motor that runs quite fast and does not consume as much battery as before. It now weighs 56 g, half as much as the previous one. After testing, this motor proved to be too bulky and unstable. So we decided to use the motor provided by the school for the rest of the project.

CREATION OF A MINIATURE MOBILE SUSPENDED TRAMWAY:

First of all we studied the train and its transmission system, we decided to take a pulley-belt system with a toothed belt by studying our state of the art.

See the video of the construction of the two trains:

Creation of the train :

As soon as the star wars theme for the project was announced, we looked for ships and their feasible designs, choosing the TIE Interceptor. We had the idea to create an Interceptor.

As soon as the star wars theme for the project was announced, we looked for ships and their feasible designs, choosing the TIE Interceptor. We had the idea to create an Interceptor.

The wheels were adapted to the new track and designed in SolidWorks, as well as new, cleaner, more practical attachments that can avoid the obstacle. A support for the motor was also modelled and laser cut.

Study of a system to stop the motor at the end of the path: using a micro switch, the limit switch is normally open, which means that :

- The switch is closed at rest, and open when pressed.

Study of a system to stop the motor at the end of the path: using a micro switch, the limit switch is normally open, which means that :

- The switch is closed at rest, and open when pressed.

The new brackets are assembled with the axles and wheels, using nuts to prevent the wheels from shifting on their axis. A wide rubber band is added to the wheels to adhere to the rail, tyres are tested and abandoned as too wide

The cab is an aluminium box in which two large holes are drilled, one at the bottom and one at the top, through which the new fasteners that hold the wheels can pass. Another hole is drilled for the motor shaft and one for the needle support.

The cab is an aluminium box in which two large holes are drilled, one at the bottom and one at the top, through which the new fasteners that hold the wheels can pass. Another hole is drilled for the motor shaft and one for the needle support.

A pin with a needle at its end is attached to the fixed attachment (at the front of the cabin) by means of a plastic pin.

Once all the parts are built, they are painted in metallic black with a paint can bought for the occasion.

The result is shown on this picture (only the belt that should connect the motor and its gear to the front of the device, and the needle axis are missing):

The result is shown on this picture (only the belt that should connect the motor and its gear to the front of the device, and the needle axis are missing):